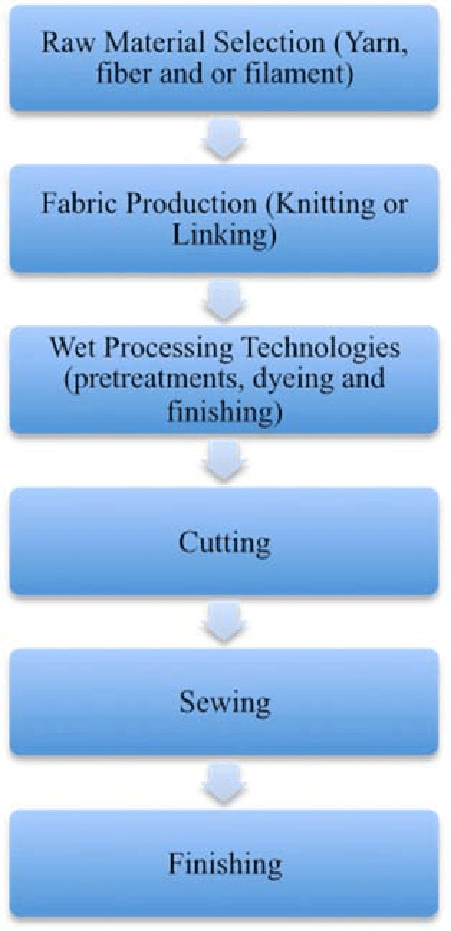

Start writing here...Producing GRS-certified knit garments means starting with recycled materials and following strict environmental and social standards. The Global Recycled Standard (GRS) ensures that a garment’s recycled content and production chain are transparent and responsibly managedabysseofficial.com. In GRS-certified sustainable knitwear, recycled yarns undergo a careful manufacturing workflow: from yarn selection and preparation, through weft and warp knitting processes on specialized machines, to fabric finishing and assembly of the finished apparel. Each step emphasizes quality and sustainability. Figure 1 below illustrates the overall knitting production flow, highlighting how yarn is tested and knitted into fabric before final grading and finishingtlr-journal.com.

Figure 1: Flow chart illustrating the knit garment manufacturing process from yarn sourcing to fabric gradingtlr-journal.com.

Yarn Selection and Preparation

The process begins with yarn selection. For GRS-certified knitwear, manufacturers procure yarns (often recycled fibers) that meet recycled-content requirements. Each batch is tested for strength, fineness, and purity to ensure it matches the order specificationstlr-journal.com. In practice, yarn is purchased per production orders and first sent to a testing lab. Technicians verify that the yarn’s physical and chemical properties meet quality standards; sub‑par yarn is rejected and returned to supplierstlr-journal.com. Approved yarns are then creelled (placed on the machine’s yarn rack) and fed into the knitting machine. At this stage, details like fabric design and stitch length are checked. Only when yarn quality and design parameters are confirmed does the machine begin productiontlr-journal.com. Careful yarn selection and testing are essential for consistent knit fabric and are a key part of sustainable garment production.

Weft and Warp Knitting Techniques

Knit fabrics are formed by interlocking loops of yarn, and the production method determines the fabric’s properties. The two main methods are weft knitting and warp knitting. In weft knitting, a single yarn is looped horizontally across the fabric. This produces rows (courses) of loops that make the fabric soft and highly stretchable, as seen in jersey and rib knitsmh-chine.com. Weft knits (also called weft-knitted fabrics) typically have good elasticity and drape, making them ideal for T-shirts, sweaters, and casual wearmh-chine.com. In contrast, warp knitting uses many parallel yarns looped vertically. This produces columns of loops that yield fabrics with excellent dimensional stability and durabilitymh-chine.com. Warp-knit fabrics (such as tricot or raschel knits) are less stretchy but retain their shape well, suitable for lingerie, swimwear, and technical textiles. These two methods offer complementary strengths: weft-knitted fabrics are flexible and comfortable, while warp-knitted fabrics are stable and robustmh-chine.comtextileschool.com.

Knitting Machines: Circular and Flat

To execute weft or warp knitting, manufacturers use specialized machinery. For weft knitting in particular, there are two common types: circular knitting machines and flat knitting machines. Circular knitting machines have a cylindrical bed of needles and produce a continuous tube of fabric. This seamless, tubular knit is ideal for high-volume apparel like T-shirts, socks, and seamless knitwearmh-chine.com. For example, a circular machine can knit the body of a sweater without side seams, improving efficiency and reducing wastemh-chine.com. On the other hand, flat knitting machines produce flat panels of fabric. They are used when garment panels (like front and back of a sweater) need to be created to shape. Flat machines allow complex shaping and patterns but require subsequent cutting and sewing of the fabric panels into the final garmenttextileschool.com. In practice, many weft-knit garments use a combination: large runs (like simple tees) on circular machines and more tailored pieces (or fine gauge knits) on flat machines. Modern machines often have digital controls and automated feeders for consistent yarn tension, which enhances quality across both circular and flat operationstextileschool.commh-chine.com. By using these knitting technologies, manufacturers can efficiently produce high-quality knit fabrics ready for finishing.

Fabric Finishing and Dyeing

After the knit fabric comes off the machine, fabric finishing processes improve its appearance, hand (feel), and performance. Typical knit fabric finishes include mechanical and chemical treatments. For example, mechanical processes like tentering and calendaring align and smooth the fabric. Chemical finishes can include mercerization (to enhance luster and dye uptake), sanforization (to reduce shrinkage), and specialty coatings (for water repellency, anti-pilling, or antimicrobial properties)textileschool.com. These treatments are chosen based on end-use: a cotton jersey T-shirt might be mercerized for brightness and sanforized for stability, while a sport knit might receive wicking or UV-protection finishes. Sustainable knitwear production favors eco-friendly finishing when possible – for instance using low-impact dyes, recycled water systems, and verified safe chemicals. The goal is to achieve the desired fabric qualities while minimizing environmental impact. Throughout finishing, quality checks ensure the fabric meets standards before moving on to garment assembly.

Final Apparel Assembly

The last stage turns finished fabric into wearable clothing. Finished knit fabric rolls are measured and graded (only top-grade rolls go forward)tlr-journal.com. Approved fabric is then cut according to pattern pieces. Skilled technicians sew these knit panels on automated cutting and sewing lines. Final steps include attaching trims (like buttons or labels) and performing quality inspections on the finished apparel. Each GRS-certified garment is labeled to certify its recycled content and sustainable production. The entire process, from yarn to final product, is carefully documented to maintain GRS chain-of-custody compliance. By the end, the company has produced a high-quality knit garment (e.g. a sweater or tee) that is both stylish and sustainably made.

Frequently Asked Questions

Q: What are GRS-certified knit garments?

A: GRS stands for Global Recycled Standard. A GRS-certified knit garment is one made from recycled materials (at least a minimum percentage set by the standard) under a verified process. The certification ensures the recycled content is tracked through the supply chain, and that the production meets environmental and social criteriaabysseofficial.com. In practice, this means the yarn (and any other materials) is certified as recycled, workers’ conditions follow fair labor practices, and no harmful chemicals are used beyond permitted limits. GRS-certified knitwear helps consumers know the garment genuinely supports recycling and sustainability goals.

Q: How do weft knitting and warp knitting differ?

A: Weft and warp are two basic knitting methods. Weft knitting loops a single yarn horizontally across the width of the fabric, creating courses of loops. This produces a soft, stretchable fabric (like jersey or rib knit) that drapes wellmh-chine.com. Warp knitting loops many yarns vertically along the length, producing columns of loops. Warp knits are typically stronger and more stable, with less stretch, making them suitable for shapely or technical fabricsmh-chine.com. In summary, weft knits (made on loop-hopping machines) tend to be stretchy and comfortable, while warp knits (made on parallel-yarn machines) are stable and resistant to distortionmh-chine.com.

Q: What roles do circular and flat knitting machines play?

A: Circular and flat knitting machines are used for producing weft-knit fabrics. Circular knitting machines have needles arranged in a tube; they knit continuously around the cylinder to make a seamless tube of fabric. This is ideal for high-speed production of items like t-shirts, socks, and tubular knit piecesmh-chine.com. Flat knitting machines, by contrast, have needles on a flat bed and knit back-and-forth to produce flat panels of fabric. These panels can be shaped for sweaters, scarves, or custom patterns and then cut/sewn into garmentstextileschool.com. In essence, circular machines offer fast, seamless knitting (lower waste), while flat machines offer flexibility in shapes and patterns. Many manufacturers use both: circular machines for standard body pieces, flat machines for detailed panels or high-end designstextileschool.commh-chine.com.

Q: Why is yarn selection important in the knit manufacturing process?

A: Yarn selection is critical for quality and sustainability. The yarn’s fiber content, strength, and uniformity determine the fabric’s feel and performance. In GRS-certified knitwear, the yarn must be verified recycled fiber. Manufacturers rigorously test each yarn batch for consistency and defects before knittingtlr-journal.com. By catching issues (like weak fibers or impurities) early, they avoid production defects in the knit fabric. Sustainable yarn choices (like recycled polyester or organic cotton blends) also reduce environmental impact. Thus, selecting and validating yarn upfront ensures the final knit fabric and apparel meet both quality standards and green certification requirementstlr-journal.comabysseofficial.com.

Q: What does fabric finishing involve in knit production?

A: Fabric finishing includes processes that enhance the raw knitted fabric’s properties. After knitting, fabric may be washed, heat-set, and chemically treated. Common finishes include mercerization (to improve luster and dye absorption), sanforization (to prevent shrinkage), and special coatings for properties like anti-pilling or water repellencytextileschool.com. In sustainable knitwear production, low-impact or Oeko-certified dyes and energy-efficient processes are used when possible. The goal is to achieve the desired texture, colorfastness, and performance without sacrificing eco-friendly standards. Proper finishing makes the fabric ready for cutting and ensures the finished garment looks and feels as intendedtextileschool.com.

Q: What is “finished apparel” in this context?

A: “Finished apparel” refers to the final knitted garment ready for sale. After knitting and finishing the fabric, the pieces are cut and sewn into the final product (for example, a T-shirt, sweater, or leggings). Finished apparel is inspected, labeled, and packaged. In a GRS-certified process, even the packaging and labeling follow certain standards. Essentially, once the fabric leaves the finishing line, the assembly steps turn it into the complete garment – this end product is the finished knitwear the consumer wears. Each piece will carry a GRS tag if certified, signifying the entire production chain has met the recycled-content and sustainability requirementsabysseofficial.com.

Sources: Authoritative textile industry references and standards guidesabysseofficial.comtlr-journal.commh-chine.comtextileschool.com were used to describe the GRS certification requirements and the technical details of knit garment production, including weft/warp differences, machine types, and finishing processes.